Are you weighing the options of buying a right CNC lathe machine to elevate your manufacturing processes? This significant investment promises to deliver increased precision and efficiency, transforming your production landscape. Let’s delve into the critical aspects to consider when buying a CNC lathe, ensuring you make a well-informed choice that aligns with your operational objectives.

Benefits of CNC Lathes in Modern Manufacturing

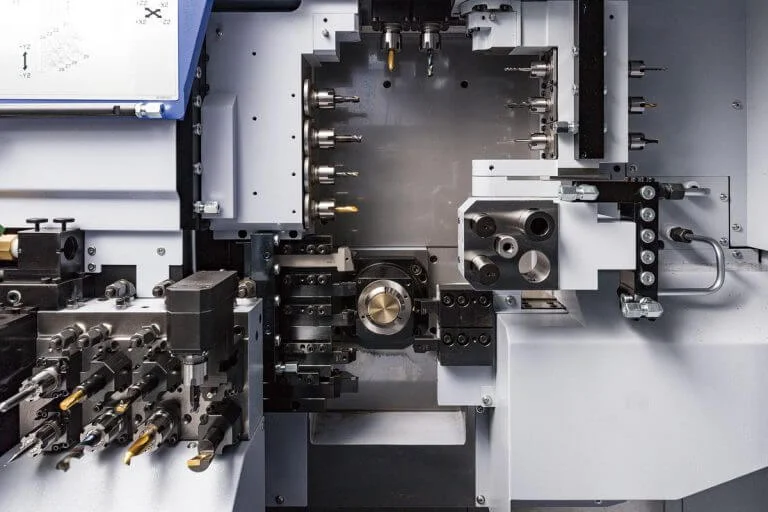

CNC lathe machines are transformative in modern manufacturing, enhancing both productivity and precision. These machines are integral for industries that demand high accuracy and efficiency.

- Increased Productivity: CNC lathes automate critical processes, allowing for faster production rates without sacrificing the quality of the output. This automation reduces the manpower needed and speeds up the entire manufacturing cycle.

- High Precision and Consistency: With advanced programming capabilities, CNC lathes produce parts with extremely high precision, ensuring consistency across large production runs. This is crucial for industries like aerospace and medical devices where precision is non-negotiable.

- Versatility: Equipped with modern technology, CNC lathes can perform a variety of machining tasks such as cutting, drilling, and finishing, all on the same machine. This versatility reduces the need for multiple machines and streamlines production processes.

- Cost Efficiency: Despite the upfront investment, CNC lathes reduce the overall manufacturing costs by minimizing waste, reducing labor costs, and increasing component quality which reduces rework and waste.

These benefits make CNC lathes a cornerstone of modern manufacturing facilities, driving efficiency and quality in production lines across various industries.

Essential Considerations When buying a CNC Lathe Machine

When selecting a CNC lathe, it’s essential to consider several key aspects to ensure the machine meets the specific needs of manufacturing operations. Here’s a detailed look at each consideration:

Type of CNC Lathe

- Turret CNC Lathes: Ideal for jobs requiring numerous tools and where tool change time is critical. These lathes are perfect for mass production setups.

- Gang-tool CNC Lathes: Gang-tool CNC Lathes are the best suited for high-speed production of parts that require a few tools. The setup allows tools to be more densely packed, which minimizes tool change time.

- Swiss-style CNC Lathes: Swiss-style Lathes are excellent for precision manufacturing of intricate parts, especially used in the medical and aerospace sectors where precision is paramount.

Size and Capacity

- It’s crucial to choose a lathe that can handle the maximum size of your workpieces. Lathes come in various sizes, and selecting one that fits your typical job size ensures efficiency and prevents the need for retooling.

Spindle Specifications

- Speed: Determines how fast the lathe can operate, which can impact production speed and finish quality.

- Power: Higher horsepower spindles can handle tougher materials and more strenuous tasks.

- Torque: Crucial for heavy-duty cutting operations, especially when working with harder materials.

Control System

- Modern CNC lathe machines come with sophisticated control systems that offer precision and ease of use. Systems from brands like Haas or Fanuc are renowned for their reliability and advanced features.

Tooling and Accessories

- Ensure the lathe can accommodate the specific tools and accessories needed for your operations. Options like live tooling, bar feeders, and tailstocks can significantly expand the machine’s capabilities.

ection Criteria

Selecting the right vendor is as crucial as choosing the machine. Consider factors like:

- Reputation and Reliability: Look for vendors known for quality and reliability.

- After-Sales Support: Comprehensive after-sales support can include training, maintenance, and readily available spare parts.

Conclusion

Investing in the right CNC lathe is a strategic decision that impacts your manufacturing operations extensively. This guide aims to arm you with the essential knowledge to make an informed decision that will enhance your production capability and ensure long-term success.

Take the next step towards optimizing your manufacturing process. Contact AMT Machine Tools experts today for a personalized consultation.