What Other Quality CNC Machine Tool Brands Does AMT Supply for You?

At AMT Machine Tools, we pride ourselves on offering a diverse range of CNC machine tool brands beyond our core offerings. We supply and distribute specialized machines from leading manufacturers like Emco, Hembrug, ETXE-TAR, and Impco. These renowned brands provide advanced solutions for CNC turning, hard turning, transfer machining, and microfinishing, ensuring we meet the varied needs of our customers across multiple industries. Whether you’re seeking precision, reliability, or innovative technology, our carefully curated selection of specialized equipment offers the perfect solutions to optimize your production processes.

Machine

EMCO: Precision Turning, Milling, and Automation Solutions

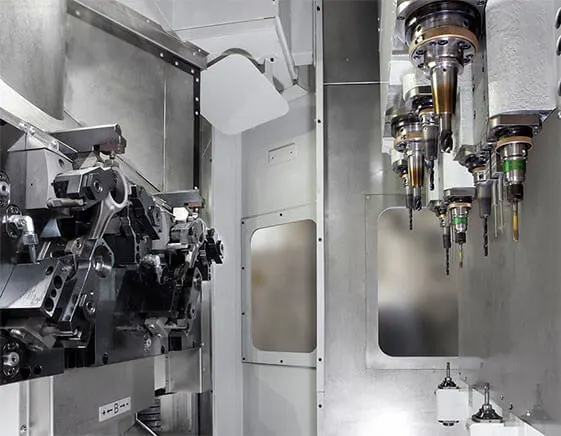

EMCO is a world-renowned manufacturer specializing in a wide range of high-precision machining solutions. Their product lineup includes CNC turning lathes, milling machines, and automation systems, all engineered to provide exceptional accuracy, efficiency, and reliability. These machines are ideal for industries such as automotive, aerospace, medical devices, and general engineering, where precision and performance are crucial to success.

EMCO’s CNC turning lathes are specifically designed to excel in high-precision turning operations. With advanced technology and robust engineering, these lathes allow manufacturers to produce intricate, high-quality components with ease and consistency. Whether handling small, complex parts or large-volume production runs, EMCO CNC turning lathes offer the versatility and precision needed to meet the strict demands of industries like aerospace and medical devices. By ensuring reliable, repeatable results, EMCO’s CNC turning lathes enhance productivity and help manufacturers achieve superior performance in their operations.

EMCO is a global leader in manufacturing advanced machining solutions, offering a wide range of high-precision machines that cater to diverse industries. From CNC turning lathes and milling machines to innovative digital solutions and automation systems, EMCO machines are designed to enhance productivity, accuracy, and efficiency. With a strong focus on precision engineering, EMCO’s machines are trusted across industries like automotive, aerospace, medical devices, and general engineering to deliver top-tier performance in even the most demanding production environments. Below is the list of EMCO machines we supply to help optimize your manufacturing process.

CNC Turning Lathes – Precision-engineered turning lathes for high-accuracy machining, ideal for industries like automotive, aerospace, and medical devices, where consistent, intricate part production is critical.

Milling Machines – Advanced milling solutions that offer exceptional accuracy and efficiency for handling complex geometries and high-speed machining, widely used in engineering, defense, and general manufacturing.

Digital Solutions – Cutting-edge software tools such as EMCONNECT, NC-Controls, and CAD/CAM Simulation, designed to enhance machine performance, monitor operations in real time, and integrate digital management of shop floor activities.

Automation Systems – Intelligent automation solutions that optimize workflow, reduce manual intervention, and boost productivity, making them ideal for high-demand production environments across various industries.

Automotive:

The automotive industry relies on precise machining for parts like engine components and transmissions. EMCO CNC Turning Lathes, Milling Machines, and Automation Systems ensure high accuracy and productivity in manufacturing critical automotive parts.Aerospace:

Aerospace requires tight tolerances and exceptional precision for components like turbine blades and airframes. EMCO CNC Turning Lathes, Milling Machines, and CAD/CAM Simulation tools are perfect for delivering the precision needed in this high-demand industry.Medical Devices:

Producing medical devices calls for extreme precision and cleanliness. EMCO CNC Turning Lathes, Automation Systems, and Digital Solutions ensure manufacturers can produce complex and delicate parts to the highest standards.General Engineering:

In the versatile field of general engineering, EMCO Milling Machines, CNC Turning Lathes, and Automation Systems provide reliable performance for both small-scale custom projects and large-scale manufacturing operations.Defense:

The defense industry requires precision and durability for military-grade components. EMCO CNC Turning Lathes, Milling Machines, and NC-Controls help produce critical components with high accuracy and reliability.Oil and Gas:

For the oil and gas industry, durable parts like pipeline valves and drilling components are crucial. EMCO CNC Turning Lathes, Automation Systems, and Milling Machines are perfect for producing these robust, high-demand components.Electronics:

Manufacturing delicate and intricate electronic parts requires exceptional precision. EMCO Milling Machines, CNC Turning Lathes, and Digital Solutions provide the accuracy needed to meet the electronics industry’s high standards.Heavy Equipment Manufacturing:

Heavy equipment demands large, durable parts, and EMCO CNC Turning Lathes, Milling Machines, and Automation Systems are built to handle the heavy-duty requirements of this industry with efficiency and precision.Renewable Energy:

For renewable energy components like wind turbines and solar panel parts, precision and durability are essential. EMCO Milling Machines, Automation Systems, and CNC Turning Lathes are ideal for ensuring high-quality, reliable parts.Job Shops:

Job shops require flexible machines that can handle a wide range of custom projects. EMCO CNC Turning Lathes, Milling Machines, and Automation Systems offer the versatility needed for diverse machining tasks, making them perfect for small-batch and custom production.

EMCO

What CNC Machine Tool Brands and Solutions Do We Offer?

We supply and distribute a wide range of CNC machine brands, including Star Swiss Style Lathes, Hydromat Transfer Machines, Cubic Machinery, Emco CNC Turning Lathes, Hembrug Hard Turning Machines, ETXE-TAR Transfer Machines, and Impco Microfinishing Machines. In addition, we offer Filtermist Oil Mist Collectors to maintain clean and safe work environments. Alongside these high-performance machines, we provide all the tools and parts needed for CNC machining, ensuring seamless operation and maximum productivity.

CNC Machine

Hembrug is the benchmark for fully hydrostatic precision hard turning solutions

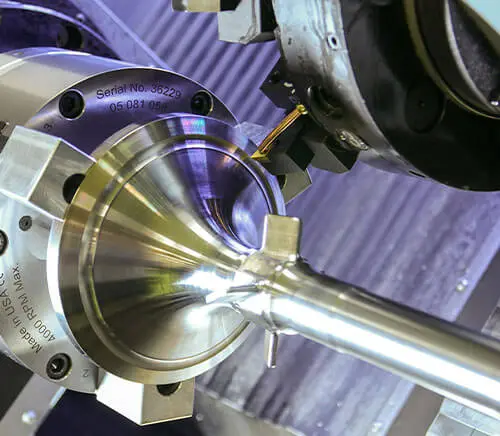

Hembrug is a leader in high-precision hard turning technology, offering state-of-the-art turning machines specifically designed for processing hardened materials. Hembrug’s hard turning machines provide an efficient and precise alternative to grinding, allowing manufacturers to machine hard materials with hardness ratings up to 70 HRC with exceptional accuracy.

These machines are ideal for industries that require high precision and durability in components, such as aerospace, automotive, tool and die, medical devices, and general engineering. Hembrug’s machines allow for the machining of hardened steel and other tough materials with minimal post-processing, reducing production time and costs.

By choosing Hembrug Hard Turning Machines, manufacturers benefit from superior surface finishes, high precision, and cost-effective production, making them a powerful solution for modern machining challenges.

Hembrug’s hydrostatic precision hard turning machines are designed to meet the rigorous demands of various high-precision industries. Here are the key industries where Hembrug machines deliver exceptional value:

Aerospace:

Hembrug machines are ideal for producing hardened components with tight tolerances, such as turbine parts, landing gear, and high-strength fasteners, ensuring high precision and durability in aerospace applications.Automotive:

In the automotive sector, Hembrug hard turning machines excel at manufacturing hardened steel components like transmission parts, gears, and engine components, providing a cost-effective and precise alternative to grinding.Medical Devices:

For the medical industry, Hembrug machines are crucial for manufacturing surgical tools and implants that require hard materials and ultra-precise dimensions to meet stringent safety and performance standards.Tool and Die:

Hembrug is widely used in tool and die production, enabling the machining of hardened tool steels with high precision, improving the quality and lifespan of dies, molds, and cutting tools.Energy:

In the energy sector, Hembrug machines provide high-precision turning for components like valve bodies, bearings, and pump parts used in oil, gas, and renewable energy systems, where durability and precision are critical.General Engineering:

Hembrug’s machines are perfect for general engineering applications that require precision machining of hard materials, improving productivity and reducing the need for costly post-processing operations.

Hembrug

Machine Tool

CNC Machine Tool Solutions: Precision and Power for Heavy-Duty Applications

CNC machines from Emco, Hembrug, ETXE-TAR, and Impco are engineered for high-performance applications, delivering precision, speed, and durability across a range of industries. Emco’s CNC turning lathes handle materials like steel, aluminum, and composites with exceptional accuracy, ideal for high-speed operations requiring tight tolerances. Hembrug hard turning machines are designed for machining hardened materials up to 70 HRC, eliminating the need for grinding and suitable for heavy-load applications with hard steels and alloys.

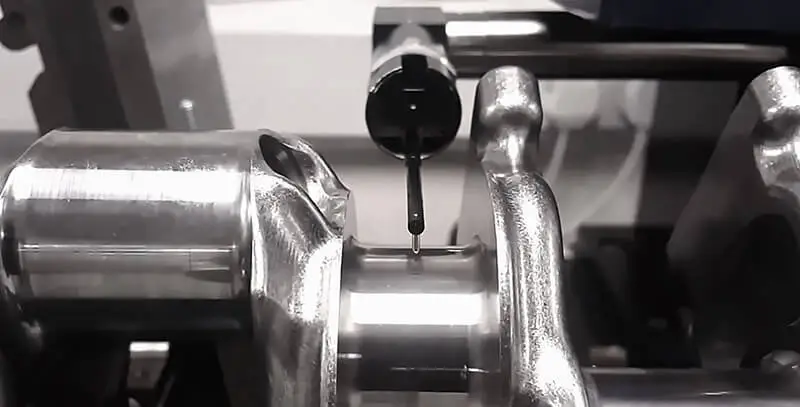

ETXE-TAR transfer machines are built for high-speed, multi-step processes, capable of handling thick, complex parts in industries like automotive and aerospace. These machines can process tough materials like cast iron, steel, and aluminum at rapid production rates. Impco microfinishing machines specialize in ultra-smooth surface finishing for components like crankshafts and camshafts, improving performance in materials such as hardened steel and cast iron.

Together, these machines are robust, fast, and adaptable, serving a wide range of material thicknesses and providing reliable solutions for heavy-duty applications. To learn more about how these CNC machine tools can enhance your manufacturing processes, or to get personalized recommendations for your specific needs, contact us today. Our team is ready to provide detailed information and help you find the perfect solution for your high-performance applications.

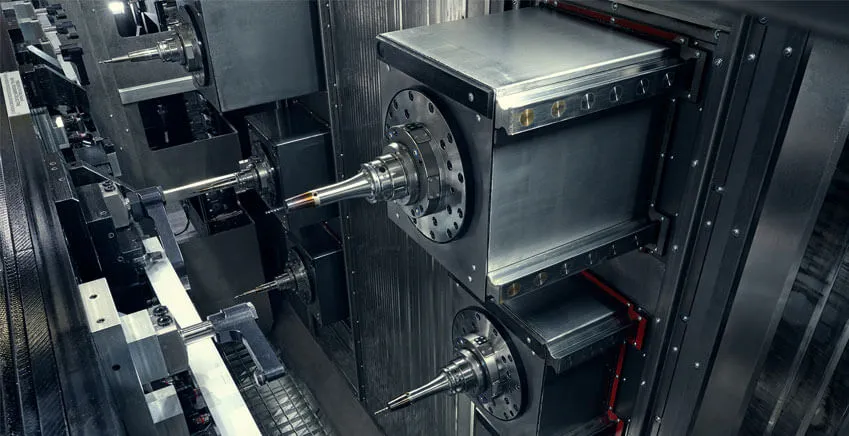

ETXE-TAR Transfer Machines: High-Performance Solutions for Mass Production

ETXE-TAR is a global leader in the design and manufacturing of transfer machines that provide high-speed, high-precision solutions for mass production. These machines are specifically built to handle complex, multi-step machining operations in a single system, allowing manufacturers to increase efficiency, reduce cycle times, and maintain consistent quality across large production volumes.

Transfer Machines by ETXE-TAR are highly specialized systems designed for the efficient mass production of precision components. These machines are ideal for high-volume manufacturing, offering fast cycle times and multiple simultaneous operations on various parts. Their circular worktables rotate components between different machining stations, enabling complex tasks like drilling, milling, and turning to be completed in one automated process.

These machines are commonly used in industries such as automotive, aerospace, and general engineering, where high precision and consistent output are critical for success. Dial Transfer Machines ensure optimized productivity while maintaining excellent quality control in large-scale production environments.

Aluminum Profiles & Castings:

Specialized machines designed for precision machining and shaping of aluminum profiles and castings, commonly used in automotive and aerospace applications.Battery Box & Big Castings:

High-capacity machines that handle large, intricate castings such as battery boxes for electric vehicles, ensuring precision and structural integrity.Flexible CNC:

A highly versatile CNC machining system capable of handling multiple operations, providing flexibility for complex, high-volume manufacturing processes.Journal Milling and Turning:

Machines designed specifically for milling and turning journal parts, ideal for the automotive and industrial sectors where precision and surface quality are critical.Special Purpose Machine:

Custom-engineered machines tailored to meet unique manufacturing needs, offering solutions for highly specific and specialized production tasks.Conrods (Connecting Rods):

Dedicated machines for the high-precision production of connecting rods, a crucial component in automotive engines, ensuring durability and performance.

ETXE-TAR transfer machines are designed to meet the high-speed, high-precision demands of various industries. These advanced systems enable manufacturers to perform multiple machining operations in one setup, reducing cycle times and boosting production efficiency. Industries such as automotive, aerospace, heavy equipment, and general manufacturing rely on ETXE-TAR machines for mass production, where precision and consistency are essential. Below are the key industries where ETXE-TAR transfer machines deliver exceptional performance and value.

Here’s a list of industries where ETXE-TAR Transfer Machines are widely used:

Automotive: High-speed, precision machining for mass production of automotive components such as engine parts and transmission systems.

Aerospace: Complex machining operations for high-precision aerospace parts, ensuring efficiency and consistent quality in production.

Heavy Equipment: Machining large, durable components used in heavy equipment manufacturing for industries like construction and mining.

General Manufacturing: Ideal for handling high-volume, multi-step production processes across a wide range of general manufacturing applications.

Energy: Machining critical components used in oil, gas, and renewable energy systems with precision and reliability.

Etxetar

Contact

Precision Microfinishing Solutions for High-Performance Industries

Impco specializes in microfinishing technology, providing advanced solutions for achieving ultra-smooth surfaces on critical components like crankshafts, camshafts, and transmission parts. Impco’s microfinishing machines ensure superior surface quality, boosting wear resistance and extending component life.

Widely used in industries such as automotive, aerospace, motorsport, and general engineering, these machines deliver the precision surface finishing needed for optimal performance and reliability. Impco’s innovative microfinishing technology offers consistent, high-quality results to meet the stringent requirements of modern manufacturing.

Automotive:

Impco pioneered the world’s first automated crankshaft microfinishing machine in 1947. Today, their systems set the standard for microfinishing quality, producing smooth, high-precision surfaces on critical automotive components like crankshafts and camshafts, enhancing vehicle performance and longevity.Aerospace:

Impco’s microfinishing solutions meet the strictest specifications, improving functional surfaces on flight-critical parts like actuators, shafts, and fuel system pumps. This ensures superior reliability and performance in aerospace operations.General Manufacturing:

Impco provides a wide range of microfinishing machines, from flexible solutions for low-volume, high-precision components to dedicated systems for OEMs. Their GBQ Microfinishing process meets the demands of various general manufacturing applications.Motorsport:

Impco’s GBQ Microfinishing process is trusted by world champions in the motorsport industry, delivering exceptional surface finishing that ensures high performance and precision in racing components.Heavy Industrial:

Impco’s flexible machine architecture supports the microfinishing of large-scale heavy industrial components, offering robust solutions for industries that demand durability and precision in massive parts.

Each of these industries benefits from Impco’s innovative microfinishing technology, designed to improve component performance and reliability across a wide range of applications.

IMPCO

What More Do You Need to Know About Emco, Hembrug, ETXETAR, and Impco?

Services

We proudly supply high-performance machines from Emco, Hembrug, ETXETAR, and Impco, offering advanced solutions for precision machining, hard turning, transfer systems, and microfinishing. To help you make the most of these industry-leading brands, we’ve compiled answers to some common questions about our support, services, and product offerings. Explore the information below to find out more about how these machines can meet your specific manufacturing needs.

What types of CNC machines does AMT offer from Emco, Hembrug, ETXE-TAR, and Impco?

AMT offers a variety of high-precision machines from these brands, including Emco CNC turning lathes, Hembrug hard turning machines, ETXE-TAR transfer machines, and Impco microfinishing systems. Each machine is designed for specific manufacturing needs, from precision turning to advanced surface finishing and high-volume production.

Which industries benefit the most from Emco, Hembrug, ETXE-TAR, and Impco machines?

These machines serve a wide range of industries, including automotive, aerospace, general engineering, heavy industrial, and motorsport. They are ideal for manufacturers who require precise machining and finishing for critical components. To learn more about the industries we serve and discover which machines are best suited for each sector, visit our Industry page for detailed insights and recommendations.