EM 1200 Milling Machine

Home | Emco CNC Machines | Emcomill 1200

The new EMCOMILL series is a CNC vertical machining center with high-performance milling spindles is designed as a moving column milling machine. The machine bed is made in welded steel, optimized by FEM analysis. The X-, Y- and Z-slides are made in cast iron.

The latest control offers milling operations, a 19” TFT colour display and 3D-reproduction and programming graphics.

It is particularly suitable for Mill, HSC- and 5 axis operations at machines up to 6 axes.

MILLING MACHINE

EMCOMILL 1200 Milling Machine Specifications and Accessories Overview

Below, all standard specifications are covered. For more information or to request a custom quote, please contact us.

Max. Machining Diameter

Ø 20mm (25/32in)

Max. Headstock Stroke Standard

STANDARD

205mm (8 in.)WITH R.M.G.B

175mm (6-57/64in)Tool Post Configuration

FRONT

Turning tool + Power-driven toolREAR

Turning tool + 4-spindle sleeve holder + Power-driven toolTool

NUMBER OF TOOLS

Front 4 tools

Rear 2 toolsTool Shank

12mm / 16mm4-Spindle Sleeve Holder

NUMBER OF TOOLS

Front 4 tools

Rear 4 toolsMAX. DRILLING CAPABILITY

Ø10mm (25/64 in)MAX. TAPPING CAPABILITY

M8 x P1.25Power-Driven Attachment

NUMBER OF TOOLS

Front 3 tools

Rear 3 toolsMAX. DRILLING CAPABILITY

Ø8mm (5/16 in)MAX. TAPPING CAPABILITY

M6 x P1.0SPINDLE SPEED

Max. 8,000min-1DRIVE MOTOR

1.0kW(continuous) / 1.2kW(5min./30%/ED)Rapid Feed Rate

35m/min -1 (X2, Z1, Z2, Y1, Y3), 20m/min -1 (X1, Y2, X3, Z3)

Main Spindle Indexing Angle

C-axis control

Main Spindle Speed

Max. 10,000 min -1

Main Spindle Motor

2.2kW (continuous)/3.7kW (10min/25%ED)

Coolant Tank Capacity

150ℓ

Dimensions (Width x Depth x Height)

2,588 x 1,300 x 1,765mm

Center Height

1,040mm (3.41ft)

Weight

3,400kg

Power consumption

4.8kVA

List of Standard

Features:

Max. Machining Diameter

Ø 20mm (25/32in)

Max. Headstock Stroke Standard

STANDARD

205mm (8 in.)WITH R.M.G.B

175mm (6-57/64in)Tool Post Configuration

FRONT

Turning tool + Power-driven toolREAR

Turning tool + 4-spindle sleeve holder + Power-driven toolTool

NUMBER OF TOOLS

Front 4 tools

Rear 2 toolsTool Shank

12mm / 16mm4-Spindle Sleeve Holder

NUMBER OF TOOLS

Front 4 tools

Rear 4 tools

List of Advanced Features:

- Tool magazine with 40 or 60 stations

- Tool holder ISO 40 / BT 40

- HSK-A63 / NC-rotary table

- Glass scales in all axes

- Handwheel

- Alarm status lamp / Control cabinet cooling unit

- Automatic tool measuring

- Coolant and air through the spindle

- Belt filter systems with high pressure pumps

ADDED OPTIONS:

Rotary Table

Hinge Type Chip Conveyor

Glass Scales in X,Y, and Z Axis

Side Tool Magazine Door

Measuring System

EMCOMILL 1200

Discover the power of the Emcomill 1200 -Milling Machine! If you have questions or need more info, just submit your request, and our team will help you. Elevate your production with the EMCOMILL 1200!

How Can the EM 1200 Improve Your Machining Process?

Process

EMCO is one of the global market leaders in CNC turning and milling machines, as well as automation solutions.

PERFORMANCE AND FLEXIBILITY WRAPPED IN A COMPACT DESIGN The flexible, vertical CNC milling machines for 3-axis milling operations have a compact machines layout, a travel of 1 800 / 1 200 or 750 mm in the X-axis, 610 mm in the Y-axis, the latest control technology, as well as a very attractive price-performance ratio. The solid fixed table and large work area enable the machining of heavy workpieces weighing up to 2000 kg.

Why Choose EMCO Milling Machines?

EMCO CNC Machine Tool Corp.

AMT Machine Tools Ltd. is the Canadian distributor of EMCO Machines, offering full access to their advanced lathes and comprehensive support. Explore our Emco Machines or contact us for more information.

OPTIONS

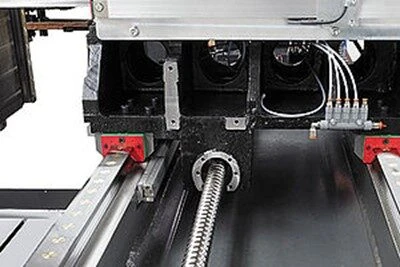

BALL SCREWS

Grease-lubricated (central) ball screws and linear roller guides (45 mm in the X- and Y-axes; 35 mm in the Z-axis) offer high resistance against mechanical stress and a high, zero-vibration traverse speed. On the picture, machine equipped with linear scales (option).

TOOL MAGAZINE

The tool magazine has 30 stations (40/60 as option). The tool management with random tool selection uses a double-gripper that allows to make a pre-search of the tool during the machining cycle. Alternatively it is possible to utilise the tool magazine with a fixed place for big-dimensioned tools, leaving the two adjacent stations free.

High performance spindle

You can choose between two variants for different areas of application: 12000 rpm (direct drive) or 15000 rpm (motor spindle).

Frequently Asked Questions about the EMCOMILL 1200 Milling machine

FAQ

How Does AMT Provide Dedicated Support for Your Emco machine?

Our commitment to customer satisfaction extends beyond the sale. Our dedicated after-sales service team is always ready to assist you with any questions or issues you may encounter. We provide prompt and reliable support to ensure your machines continue to operate at peak performance.

Is Technical Support Available for Your emco cnc machine?

Our technical support team is available to provide immediate assistance. Whether you need troubleshooting help or technical advice, our experts are just a phone call away.

How Can You Access Spare Parts and Tooling for Your Emco cnc machine?

At AMT Machine Tools, we ensure that your investment in a Emco CNC Machine is fully supported with comprehensive after-sale service, including expert installation, training, ongoing maintenance, and technical assistance, all designed to maximize the performance and longevity of your equipment.

What Maintenance Services Does AMT Offer for your emco cnc machines?

We offer comprehensive maintenance services for your Emco machine, including routine scheduled upkeep to ensure optimal performance and preventive maintenance programs that proactively identify and address potential issues. Our tailored approach helps extend equipment lifespan, prevent unexpected breakdowns, and minimize downtime.

How Can AMT’s Consultation Services Help You Select the Right Emco cnc machine?

Our knowledgeable consultants offer expert guidance in selecting the perfect Emco CNC Machine for your specific needs. We take the time to understand your operational challenges and recommend tailored solutions that enhance productivity and efficiency in your machining processes.