Why Are Hydromat Rotary Transfer Machines

one of the Best Choices for Precision & Innovation?

Hydromat Rotary Transfer Machines, crafted in St. Louis, Missouri, are the product of over 40 years of commitment to precision and innovation. As the trusted distributor of Hydromat in Canada, AMT Machine Tools is proud to offer these advanced systems to customers across the country. Hydromat blends Swiss precision with locally sourced components, delivering high-quality, cost-effective machining solutions. Their modular systems are designed for versatility and productivity, making Hydromat a trusted name in the precision transfer machine industry.

rotary

Hydromat’s dedication goes beyond manufacturing. Their attention to detail during production is matched by their comprehensive customer support. From maintaining a vast parts inventory to offering exceptional engineering and customer service, Hydromat ensures clients are supported at every stage. Their continuous focus on improvement and customer satisfaction helps businesses gain a competitive edge in their industries.

What industries benefit the most from Hydromat's rotary CNC machines?

Industries such as automotive, medical, industrial products, and aerospace benefit significantly from the advanced capabilities of rotary CNC machines. These sectors require the production of complex parts with high precision and in large volumes, where efficiency and accuracy are paramount. The versatility of rotary CNC machines allows manufacturers to handle diverse tasks, from machining intricate medical components to producing robust automotive parts, all while maintaining tight tolerances. The robust design and advanced technology embedded in these machines ensure long-term reliability and adaptability to changing production needs, making them an ideal solution for industries that demand both high performance and flexibility in their manufacturing processes.

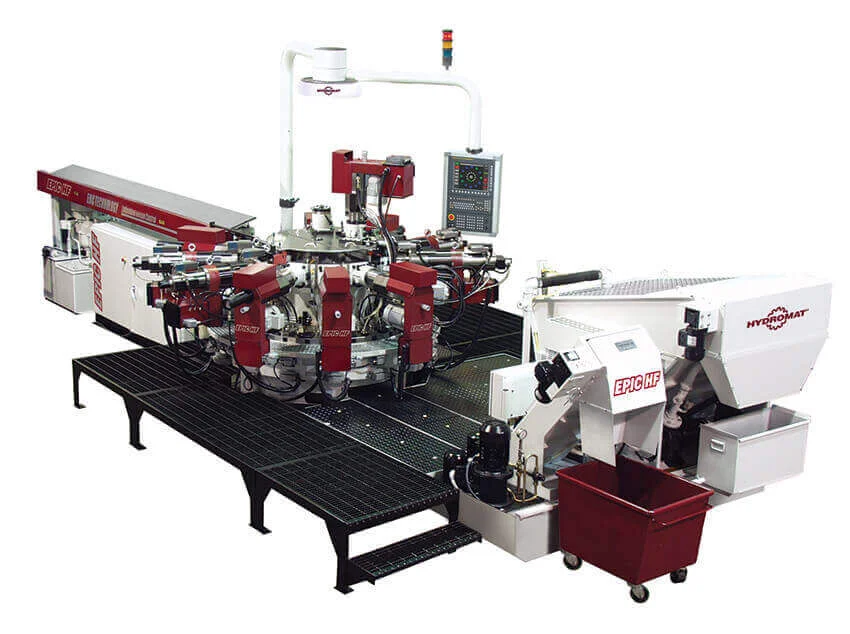

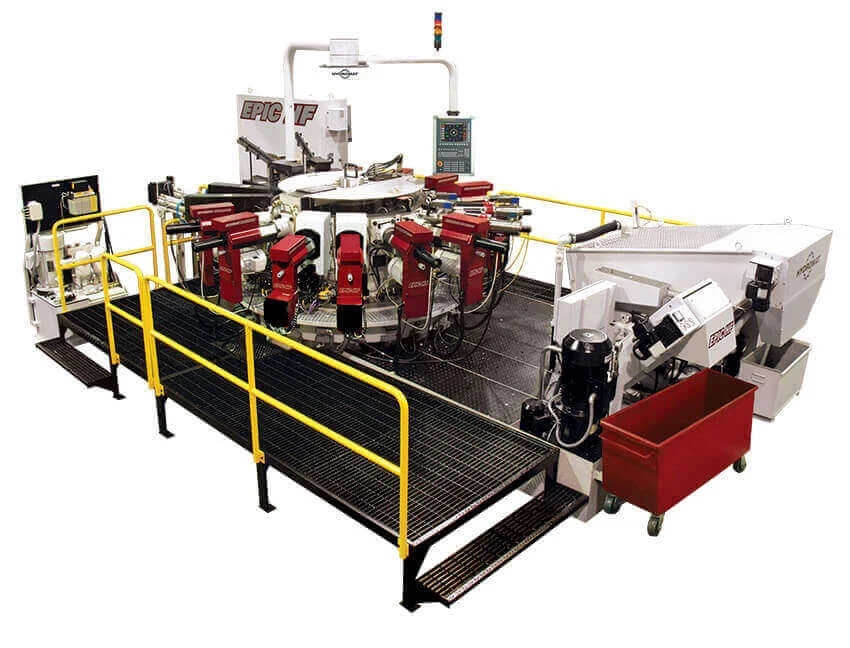

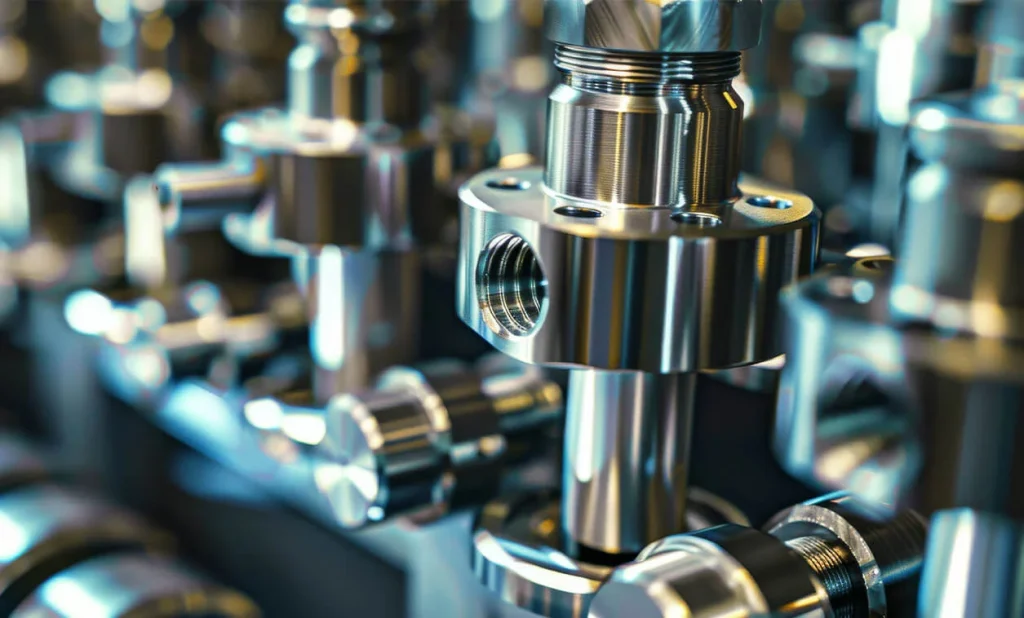

In the industrial products industry, precision and durability are essential for manufacturing components like gears, valves, and fittings used in various machinery and equipment. Hydromat’s EPIC HF is well-suited for this sector, offering up to 16 horizontal and 8 vertical machining stations. This machine handles blanks up to a 4.000″ cube, making it ideal for producing robust, complex parts with high accuracy and repeatability. The EPIC HF’s advanced CNC controls and flexible setup allow for quick changeovers, ensuring that manufacturers can efficiently produce high volumes of industrial components while maintaining tight tolerances and superior quality.

The automotive industry demands high-volume production with exacting precision, particularly for components such as engine parts, transmission systems, and brake elements. The EPIC HF rotary transfer machine from Hydromat is designed to meet these needs, featuring 16 horizontal and 8 vertical machining stations for multi-axis operations. Capable of handling bar stock up to 1.75″ in diameter, this machine excels in producing complex automotive parts with minimal cycle times. The EPIC HF’s CNC programming capabilities and high-speed indexing ensure consistent quality across large production runs, reducing the need for secondary operations and improving overall efficiency.

In the medical industry, precision and cleanliness are essential for manufacturing components used in surgical instruments, implants, and diagnostic devices. The Hydromat EPIC HF 25-12 Rotary Transfer Machine is an ideal solution for this sector, offering simultaneous multi-operation machining with up to 12 horizontal tool spindles and 6 vertical tool spindles. This machine excels at producing complex medical components with tight tolerances and can handle a variety of materials used in medical manufacturing. The FANUC 30i-B CNC control system ensures precision and consistency, while its multi-tool capacity and advanced monitoring systems deliver superior surface finishes, meeting the stringent demands of the medical industry.

The defense and aerospace industries require extreme precision and reliability, as components often function under high-stress conditions. The Hydromat EPIC HF 32/45-16 Rotary Transfer Machine is specifically designed to meet these stringent demands, offering 16 horizontal tool spindles and 8 vertical tool spindles for simultaneous multi-operation machining. This machine excels at handling complex materials and part geometries, making it ideal for producing high-precision components such as aerospace fittings and structural elements. With its robust construction and advanced FANUC 30i-B CNC controls, the EPIC HF 32/45-16 ensures that every part is manufactured with exact specifications, providing the accuracy and durability required for defense and aerospace applications.

INDUSTRIES

How Will AMT Support You for your Hydromat Rotary Transfer Machines?

Services

At AMT Machine Tools, we understand that investing in a Hydromat rotary transfer machines is just the beginning of your journey toward enhanced production efficiency and precision. That’s why we are committed to providing comprehensive support every step of the way. From routine maintenance and expert technical assistance to a readily available inventory of spare parts and tooling, our services are designed to keep your operations running smoothly. Additionally, our consultation services ensure that you can continuously optimize your machine’s performance to meet evolving production demands. With AMT, you’re not just purchasing a machine—you’re gaining a dedicated partner in your success.

How Does AMT Help Maintain Your Hydromat Machine?

When technical challenges arise, AMT’s experienced support team is just a call away. We provide prompt troubleshooting assistance to resolve issues quickly, whether they are mechanical, electrical, or software-related. For more complex problems, our technicians can visit your site to diagnose and fix issues, minimizing disruption to your operations. We understand the critical role your Hydromat machine plays in your production line, and our support is designed to get you back up and running as swiftly as possible.

What Kind of Technical Support Can You Expect from AMT?

When you choose AMT, you can expect top-notch technical support for all your machine tools. Our services include expert troubleshooting, on-site repairs, and tailored preventive maintenance to ensure your equipment runs at peak performance. We also offer comprehensive training for your team, along with upgrade and retrofitting options to keep your machines current with the latest technology. AMT is committed to providing the support you need to maximize productivity and ensure long-term success.

How Quickly Can AMT Provide Spare Parts and Tooling for Your Hydromat Machine?

AMT maintains a comprehensive inventory of genuine Hydromat spare parts and tooling, ensuring you have quick access to the components you need. Whether it’s a routine replacement or an urgent repair, we can supply the parts to keep your machine functioning efficiently. Our fast and reliable parts service reduces downtime and helps you maintain consistent production quality, providing peace of mind that your operations won’t be stalled by unexpected delays.

How Can AMT's Consultation Services Optimize Your Hydromat Machine's Performance?

AMT offers expert consultation services to help you get the most out of your Hydromat transfer machines. Our specialists work with you to assess your current operations and identify areas where your machine’s performance can be enhanced, whether through process optimization, upgrades, or adjustments to meet new production requirements. We provide tailored recommendations that align with your specific goals, ensuring that your Hydromat machine continues to deliver maximum value as your production needs evolve.