High-Precision Turning: Star CNC Swiss Lathes for Intricate Component Manufacturing

Discover how Star CNC Swiss Lathes deliver unmatched precision in manufacturing. Advanced multi-axis capabilities for medical, aerospace & automotive industries.

Understanding the Life Expectancy of a CNC Lathe: A Detailed Overview

Understanding the life expectancy of a CNC lathe is crucial for engineering managers to optimize asset management and maintenance schedules. This guide delves into how material quality, usage frequency, and regular maintenance can significantly impact the longevity of CNC lathes.

Buying a CNC Lathe: Essential Guide for Engineering Managers in Canadian Manufacturing

Explore essential considerations for buying a CNC lathe in Canada, ensuring a well-informed purchase that enhances manufacturing precision and operational efficiency. This guide serves as an invaluable tool for engineering managers looking to elevate their production capabilities.

Enhancing Work Environment: Workplace Oil Mist Collectors Improve Air Quality

Workplace oil mist collectors are essential for maintaining superior air quality in industrial environments. Learn how these systems utilize advanced filtration technologies like HEPA filters to capture and remove airborne oil particles, thereby safeguarding both employee health and machinery efficiency.

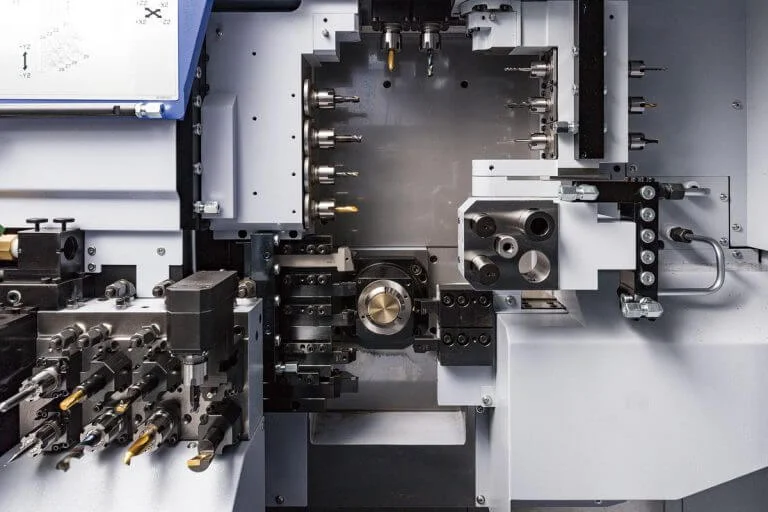

CNC Lathe Machines: The Future of Precision Manufacturing Is Here

CNC lathe machines have become integral to modern manufacturing, offering unmatched precision and efficiency across various industries. These advanced machines transform raw materials into finished parts with exceptional accuracy, significantly enhancing productivity and reducing waste. Whether it’s automotive, aerospace, or medical industries, CNC lathe machines provide the technological backbone for producing complex parts that meet stringent quality standards.

Boosting Productivity: Maximizing CNC Lathe Efficiency for Modern Manufacturing

Explore advanced techniques and best practices to maximize CNC lathe efficiency in today’s data-driven manufacturing environment. Learn how to optimize cycle times, reduce waste, and enhance the effectiveness of your CNC operations through program optimization, tool management, and strategic process monitoring.

Unlocking Profitability: Advanced CNC Machining ROI for Canadian Manufacturers

Discover how Canadian manufacturers can boost their ROI with Advanced CNC Machining. This guide covers everything from reducing production costs to enhancing part quality and efficiency. Learn practical strategies for optimizing your CNC operations and securing a competitive edge in the market.

Optimizing Manufacturing Processes with Advanced CNC Machining in 2025

In today’s competitive landscape, are you confident your manufacturing processes can meet the demands of 2025 and beyond? The need for increased precision, efficiency, and adaptability is undeniable. Advanced CNC machining offers a strategic advantage, enabling manufacturers to overcome challenges and unlock new opportunities. This post explores how cutting-edge CNC solutions are transforming key industries, empowering businesses like yours to achieve peak performance. We’ll examine specific applications and directly address the concerns of key decision-makers.

CNC Machining for Medical Devices: Precision in Implants and Instruments

CNC Machining for Medical Devices plays a pivotal role in the medical industry by enabling the production of high-precision medical implants and instruments. This technology ensures that these components meet rigorous safety and functionality standards, crucial for patient care and medical procedures.

CNC Lathe vs Manual Lathe vs Automatic Lathe: A Comprehensive Guide for Modern Manufacturing

Choosing between CNC, manual, and automatic lathes is crucial for optimizing manufacturing processes. This guide provides a detailed comparison of their capabilities, costs, and applications, helping manufacturers make informed decisions. Whether enhancing precision, increasing production volume, or maintaining craftsmanship, understanding the differences between these lathe types is essential for aligning with specific manufacturing goals.