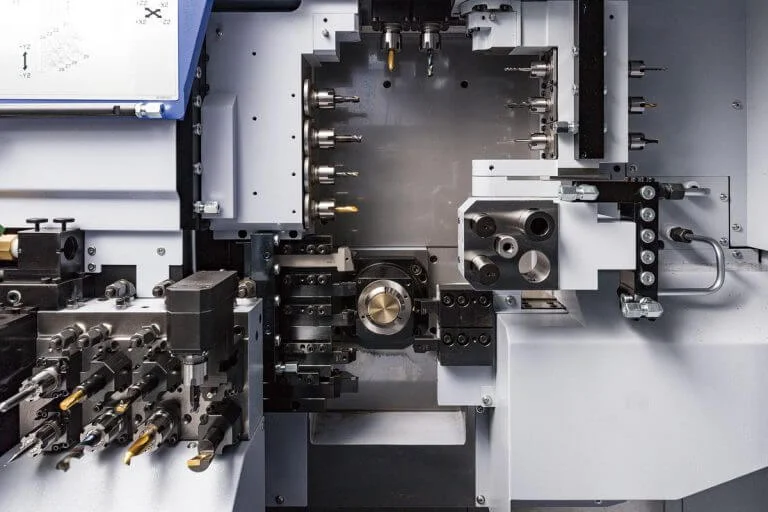

SR-38 Type B CNC Swiss-type Automatic Lathe

The SR-38 Type B CNC Swiss Lathe is a powerful, high-precision Swiss-type machine, built to handle large, complex parts with unmatched efficiency. Featuring advanced 10-axis control, this machine excels in simultaneous multi-tool operations, delivering high-speed performance for demanding applications like turning, milling, and drilling.

- Spindle speeds up to 7,000 RPM

- Supports up to 41 tool positions for maximum versatility

- 10-axis control with simultaneous machining for increased productivity

Lathe

SR-38 Type B 10-Axis CNC Swiss-type Automatic Lathe Specifications and Accessories Overview

The SR-38 Type B delivers advanced performance with a maximum machining diameter of 38mm, supported by a 320mm headstock stroke and B-axis control, providing unparalleled flexibility for complex part geometries. Its rigid machine construction and high-precision tool post allow for continuous machining with accuracy over extended production runs. The 8-spindle backworking unit with Y-axis control enables the machine to perform multiple operations simultaneously, optimizing efficiency and reducing cycle times.

This lathe is equipped with a 5-spindle sleeve holder, cross-milling tools capable of up to 6,000 RPM, and a main spindle motor rated at 7.5kW, offering power and speed for demanding machining tasks. The C-axis control for both main and sub-spindles further enhances the machine’s ability to perform secondary machining operations with precision. With a 253-liter coolant tank, the SR-38 Type B maintains optimal temperatures, extending tool life and ensuring consistent machining performance.

Read the full technical specifications below. To learn more or to get your custom quote today, contact us and discover how the SR-38 Type B CNC Swiss-Type Automatic Lathe can elevate your operations.

Max. Machining Diameter

Ø38mm (1-1/2in)

Max. Headstock Stroke

WITH R.G. B. UNIT

320mm(12-19/32in)

WITH R.M.G.B. UNIT

288mm(11/32in) : OPTool

5 tools on the front (stationary type) + 2 tools on the rear (X3 axis control)

5-Spindle Sleeve Holder

NUMBER OF TOOLS

Front 5 tools

Rear 5 tools

MAX. DRILLING CAPABILITY

Ø23mm (29/32 in)

MAX. TAPPING CAPABILITY

M16 x P2.0Power Driven Attachment

CROSS MILLING

4 tools

CARTRIDGE TYPE

At 2 position

NUMBER OF TOOL (TYPE A)

Angle adjustable power-driven tool At 1 position (front 3 tools + rear 3 tools)

NUMBER OF TOOLS (TYPE B)

B-axis controlled power-driven tool unit At 1 position (front 3 tools + rear 3 tools)

MAX. DRILLING CAPABILITY

Ø10mm (25/64in)

MAX. TAPPING CAPABILITY

M8 x P1.25

SPINDLE SPEED

Max 6,000min-1

Drive Motor

2.2kw (continuous) / 4.0kw (5 min./30% ED)Rapid Feed Rate

36m/min(X1, Y1, Z1, X2, Z2), 24m/min (Y2, X3)

Main Spindle Indexing Angle

C-axis control

Main Spindle Speed

Max. 7,000min-1

Main Spindle Motor

7.5kw (continuous) / 11kw (10min./25%ED)

Coolant Tank Capability

253ℓ

Dimensions (Width x Depth x Height)

2,740 x 1,315 x 2,120mm

Weight

4,300kg

Power Consumption

16.9 KVA

Max. Chucking Diameter

Ø38mm (1-1/2 in)

Max. Length For Front Ejection

150mm (5-7/8in)

Max. Parts Projection Length

70mm (2-3/4in)

Back 8-Spindle Unit

NUMBER OF TOOLS

8 tools

MAX. DRILLING CAPACITY

Stationary Tool

Ø14mm (35/64in)

Power-Driven Tool

8 tools

MAX. TAPPING CAPACITY

Stationary Tool

M12 x P1.75

Power-Driven Tool

M6 x P1.0Power-Driven Att. Spindle Speed

Max. 6,000 -1

Power-Driven Att. Drive Motor

1.0kw (continuous) / 1.2kw (5 min./30% ED)

Sub Spindle Indexing Angle

C-axis control

Sub Spindle Speed

Max. 7,000min-1

Sub Spindle Motor

3.7kw (continuous) / 5.5kw (10min./40%ED)

- CNC unit Fanuc 31i-B (Type A) and CNC unit Fanuc 31i-B5 (Type B)

- Operation Panel 10.4 inch color LCD Display

- Pneumatic unit

- Hydraulic unit

- Automatic centralized lubrication unit

- Coolant level detector

- Door interlock system

- Broken cutoff tool detector

- Drive unit for revolving guide bush

- Revolving guide bush unit

- Air purge for revolving guide bush

- Main/Sub collet

- C-axis control (main/sub)

- Spindle clamp unit (main/sub)

- 5-Station tool holder (16/20mm)

- 2-Station tool holder (16mm)

- 5-Spindle sleeve holder

- Cross milling tool unit (4-tool type)

- Angle adjustable 3-Spindle opposing unit (Type A)

- 3-Spindle opposing unit with B axis control (Type B)

- Air purge for sub spindle

- 8-Spindle back working unit with Y-axis control function

- 8-Spindle back working unit power tool drive

- Parts conveyor

- Work light

- Leakage breaker

- Coolant flow detector

- Parts ejection detector

- Water removal unit

- Beacon

- Chip conveyor

- Rotary magic guide bush unit

- For pneumatic unit rotary magic guide bush

- Main spindle inner tube

- Non-guide bush type

- Parts ejector (Air cylinder type)

- Spacer Set

- Parts ejector (Spring type)

- Parts ejector with guide tube

- Parts stopper unit

- Coolant unit (6.9MPa / 2.5MPa / 0.7 MPa)

- Coolant tank large capacity type

- Coolant unit signal cable

- Coolant unit power cable

- Coolant valve (6.9 MPa / 2.5 MPa)

- Coolant pipings

- Automatic bar feeder interface

- Compliant with the RS-232C interface

- LAN interface

- Transformer CE marking version

- Transformer CE marking cable

- CE marking version

SR-38

Discover the power of the SR-38 Type B 10-Axis CNC Swiss-type Automatic Lathe! Download our brochure to learn about its features and specifications. If you have questions or need more info, just submit your request, and our team will help you. Elevate your production with the SR-38 Type BB !

How Can the SR-38 Type B Improve Your Machining Process?

Process

The SR-38 Type B 10-Axis CNC Swiss-Type Automatic Lathe can significantly improve your machining process through its advanced design and features. Its compact footprint makes it suitable for facilities with limited space while still offering extensive machining capabilities. The independent X3 slide allows for balanced cutting, maximizing metal removal and precision—crucial for high-complexity and high-precision components.

Equipped with Fanuc’s 31i-B5 control system, the SR-38 Type B offers full five-axis control, making it ideal for producing intricate parts with tight tolerances. The tilting B-axis tool post and Y2 axis enable versatile tooling options, allowing for a wide range of angular work and cross-working operations, thus increasing machining flexibility.

The machine’s sub-spindle with an 8-station platen supports overlapped machining, reducing cycle times and increasing overall productivity. Additionally, with powerful spindle performance (up to 11kW for the main spindle and 5.5kW for the sub-spindle) and 7,000 RPM speeds, the SR-38 Type B ensures robust operation for demanding machining tasks.

Its high machining capacity, handling raw materials up to 42mm in NGB mode, expands its range of applications. With thermal stability ensured by advanced sensors for displacement correction, the machine maintains consistent accuracy even under varying conditions, making it highly reliable for precision tasks.

Finally, the convertible headstock design provides operational flexibility, enabling the machine to switch between sliding and fixed headstock modes to meet diverse production needs. This adaptability, combined with STAR Micronics’ training and support services, ensures that the SR-38 Type B delivers long-term, efficient performance in your machining operations.

Why Choose Star Swiss-Style Lathes?

Star CNC Machine Tool Corp., a division of Star Micronics Co., Ltd. of Japan, is a global leader in Swiss-type turning machines, known for producing small, complex, and precise metal components. Since 1948, Star CNC has delivered reliable, high-performance lathes that excel in both high-volume production and intricate part fabrication.

Their mission is to develop fast, efficient, and robust machines that meet the demands of today’s 24/7 production environments, with a focus on ergonomics, safety, and environmentally-friendly operations.

AMT Machine Tools Ltd. is the Canadian distributor of Star CNC, offering full access to their advanced lathes and comprehensive support. Explore our Star Swiss-style lathe page or contact us for more information.

Frequently Asked Questions about the SR-38 Type B 10-Axis CNC Swiss-type Automatic Lathe

FAQ

What are the main differences between the SR-38 Type B and the SR-20JII Type B?

The primary differences between the SR-38 Type B and the SR-20JII Type B lie in their machining capacities and axis configurations. The SR-38 Type B supports a larger maximum machining diameter of Ø38mm (1-1/2in), compared to the SR-20JII Type B’s Ø20mm (25/32in). Additionally, the SR-38 Type B operates with a 10-axis control system, offering enhanced precision and versatility for complex machining tasks, while the SR-20JII Type B features an 8-axis system. The SR-38 Type B also boasts B-axis control, providing more versatility for angular and intricate part machining, a feature not found in the SR-20JII.

How does the SR-38 Type B handle complex machining tasks?

The SR-38 Type B excels at handling complex machining tasks thanks to its 10-axis control system, which allows for multi-axis machining and simultaneous overlapping operations. Its rigid machine construction, combined with built-in main and sub-spindles and high tool post rigidity, ensures precision and accuracy, even for intricate parts. The inclusion of an 8-spindle backworking unit further enhances the machine’s ability to perform complex operations in a single setup, significantly improving efficiency.

What industries benefit most from the SR-38 Type B’s capabilities?

Can the SR-38 Type B handle high-volume production efficiently?

Yes, the SR-38 Type B is well-suited for high-volume production. Its robust design, high-speed spindle performance, and rapid feed rates ensure consistent, reliable output. The machine’s powerful 11kW main spindle motor, high-speed sub-spindle, and efficient feed rates enable it to maintain high productivity over extended production runs, making it ideal for environments requiring continuous, high-volume machining. Did you download CNC Swiss type automatic lathe brochure?

What are the unique advantages of the SR-38 Type B’s design?

The SR-38 Type B offers several key design advantages, including B-axis versatility for angular and complex machining, a proprietary Motion Control System that reduces idle time, and low energy consumption for an environmentally-friendly operation. Its compact yet powerful design, combined with advanced control systems and overlapped machining capabilities, ensures maximum efficiency. Additionally, the support and training provided by STAR Micronics GmbH help manufacturers fully leverage the machine’s capabilities, making it an invaluable addition to any production line.